FEED MILL GRINDING & ROLLING CONTROL SYSTEMS

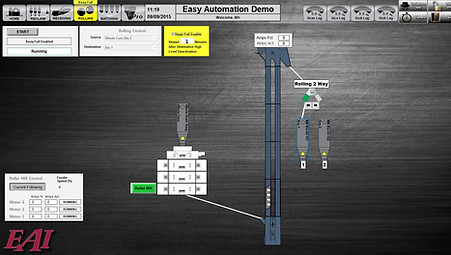

With EAI’s Grinding and Rolling Control package, you have total control over your process. Features like auto gap control, bin keep full, and mill optimization keeps your system working hard for you. Our feed mill grinding and rolling control system adapts to any hammer mill with forward and reverse controls. Constant monitoring ensures your system shuts down safely if the need arises. This control system is designed to maximize your feed mill operation’s efficiency.

Feed Mill Grinding &

Rolling Controls

GRINDING & ROLLING

AUTO GAP CONTROL (ROLLING)

The right gap setting should create the perfect grain consistency without overloading the roller. EAI’s automation technology allows for custom gap settings to suit your specifications. Our Rolling Control system’s auto-gap feature adjusts rolls to the desired gap setting. This ensures optimum grain quality and an efficient rolling process.

BIN KEEP FULL

The keep-full mode allows the roller mill to start and stop automatically to keep rolled bins full at all times. This allows you to maximize time and efficiency and minimize grain waste from overflowing bins. The HMI allows you to select one or more source bins direct finished product as desired.

HMI EQUIPMENT CONTROL

EAI’s Grinding and Rolling Controls give its user on-screen control of any roller mill or hammermill in their system. It optimizes throughput by adjusting feeding rates to maximize amp loads. The HMI screen is also user-friendly, which helps operators learn the system quickly. The interface also optimizes daily tasks.

AUTOMATIC SHUTDOWNS

Our feed mill grinding and rolling control system monitors settings constantly. Its design enables it to not only identify risks, but also implement solutions when applicable. In the event that operator intervention is necessary, the system will alert personnel and initiate automatic system shutdowns. This failsafe gives you the peace of mind that your operation runs safely and efficiently at all times.

MOTOR STARTER PANELS

-

Factory engineered and assembled to customer's specific needs

-

Compact IEC style starters and contactors provide easy serviceability and allow more components in a smaller space.

-

Variable Frequency Drives (VFD) and soft starts are wired and programmed for specific applications.

-

Easy expansion of panels with custom schematics, terminal block layouts, and block diagrams speed up installation and troubleshooting.

-

Panels are UL approved.