MICRO INGREDIENT SYSTEMS

Durable design and innovative technology customized to your facility.

Scroll Down

Easy Automation, Inc. is dedicated to providing precise and efficient solutions for ingredient handling. Our micro ingredient systems deliver exceptional accuracy to ensure consistent results for every batch. With durability and reliability at the forefront, our systems streamline operations, minimizing waste and increasing productivity.

Our automated ingredient systems incorporate state-of-the-art technology to simplify complex processes. By automating ingredient handling, these systems reduce manual intervention, improve workflow efficiency, and maintain high standards of quality control. Operators can confidently manage production with real-time controls and accurate software integration.

We have a robust offering of automated micro ingredient systems developed to meet your facility's needs today and in the future. These micro ingredient batching systems are offered in several configurations to adapt to your existing space. Whether you're building an entirely new facility or retrofitting an existing space we have a custom solution for your specific needs. We currently offer three different tiers of systems, all of which are built with integrity and quality. Be sure to view the on-site photos below.

Models & Variations

Industrial "I" Line

Stainless Steel Gain in Weight Micro System

Standard "S" Line

Stainless Steel Gain in Weight Micro System

Industrial "I" Line

Stainless Steel Loss in Weight Micro System

Standard "S" Line

Stainless Steel Loss in Weight Micro System

Standard "S" Line

Stainless Steel Funnel Scale Micro System

Poly "P" Line

Gain In Weight Micro System

Cattle Application Micro System

Industrial "I" Line Details & Specifications

The industrial “I” line micro ingredient system features top-of-the-line specifications that is uniquely designed for the demands of brand-new, high-capacity feed mills expecting to run 24 hours a day for decades to come. Offered in several configurations, these systems can adapt to your existing space. The modular hopper design provides for an unlimited number of configurations and the ability to easily expand to meet the needs of your changing facility. Our micro ingredient systems can be used with any batching system.

FEATURES & SPECIFICATIONS

+ Stainless Steel Bins

+ 4” Standard High-Performance Feeder Screw with Variable Length and Depth Pitch Flighting Patterns

+ Dodge Gearboxes

+ NEMA 4 Quick Connect Cords

+ 45 or 65 Degree Bin Wall Slope

+ S Type, Class IIIL Load Cells

+ Stainless Pneumatic Rotary Scale or Funnel Stainless Funnel Discharge

MOTOR OPTIONS

+ 1 HP TEFC Motor

+ 3/4 HP Explosion Proof Motor

MICRO BIN SIZES

+ 5.7 cu. ft.

+ 7.5 cu. ft.

+ 9.5 cu. ft.

OPTIONAL/ ADD ON

+ Platform & Stairs

+ 4” Ultra-High Accuracy Feeder Screw

+ Upgraded Bin Lid Types

+ Heavy Duty Inlet Grate

Standard "S" Line Details & Specifications

The standard “S” line micro ingredient system features high-quality specifications and is uniquely designed for both new construction or adding a micro ingredient system to a commercial facility. This design provides a high-quality design at a competitive price. Offered in several configurations, these systems can adapt to your existing space. The modular hopper design provides for an unlimited number of configurations and the ability to easily expand to meet the needs of your changing facility. Our micro ingredient systems can be used with any batching system.

FEATURES & SPECIFICATIONS

+ Stainless Steel Bins

+ Hinged Bin Lids with Handles

+ Stainless Variable Pitch Augers

+ NTEP High Accuracy Load Cells

+ Weigh Back Feature for Inventory Reconciliation

MOTOR OPTIONS

+ 3/4 HP TEFC Motor with Gearbox

+ 3/4 HP Explosion Proof Motor

MICRO BIN SIZES

+ 4 cu. ft.

+ 8 cu. ft.

+ 16 cu. ft.

OPTIONAL/ ADD ON

+ Platform & Stairs

+ Load Cells can be NTEP Certified within 0.05 lbs.

+ Dust Collection Lids

+ Quick Connect Cords

+ Funnel Scale Options

+ Low Ingredient Inclusion Package

Poly "P" Line Details & Specifications

Our poly "P" line micro ingredient systems provide a high-quality design at a competitive price. Offered in several configurations, these systems can adapt to your existing space. The modular hopper design provides for an unlimited number of configurations and the ability to easily expand to meet the needs of your changing facility. Our micro ingredient systems can be used with any batching system.

FEATURES & SPECIFICATIONS

+ Polyethylene Ingredient Bins

+ Stainless Steel Discharge Tubes, Lids & Hardware

+ Flex Auger located on bin discharge

+ Heavy-Duty 2 Speed Motors

+ High Accuracy Load Cells

+ Standard U-Trough Flush Weigh Hopper

+ Weigh Hopper Discharge

MOTOR OPTIONS

+ 3/4 HP TEFC Motor with Gearbox

+ 3/4 HP Explosion Proof Motor

MICRO BIN SIZES

+ 4.6 cu. ft.

+ 9.2 cu. ft.

OPTIONAL/ ADD ON

+ Flush Hopper for Multi-Stage Systems

+ Optional Discharge Configuration available to match to MFP or discharge auger. Removable top plate allows for easy cleanout

+ Upgrade to Stainless Steel U-Trough Weigh Hopper

+ 2.8 cu. ft or 5.6 cu. ft bin sizes

Easy Automation Micro System Product Line

Customer Example - Micro Upgrade

Protein Sources Milling

Mapleton, MN

28 Bin Stainless Steel Micro System Upgrade

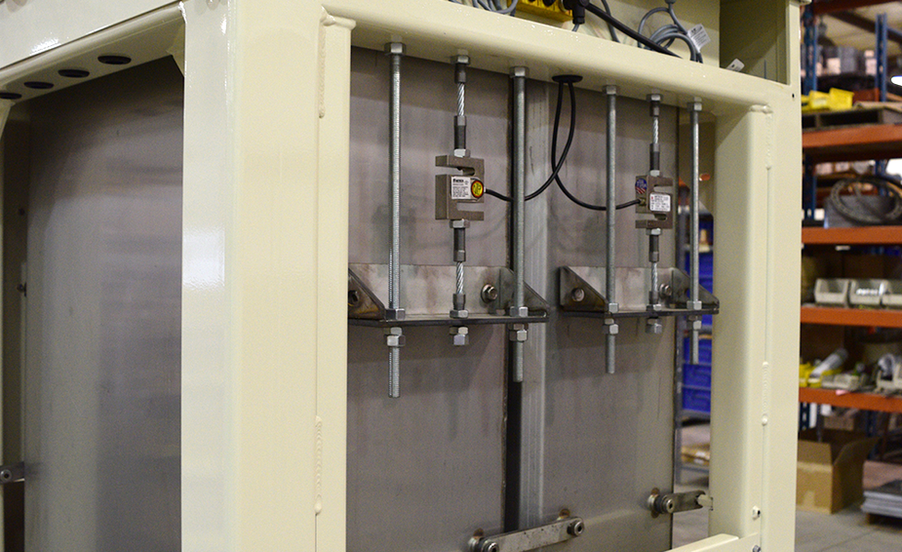

Micro Ingredient Systems On Site Photos

The micro ingredient dosing system offers unparalleled precision in measuring and dispensing even the smallest quantities of ingredients. This innovation allows for meticulous tracking and management, critical for industries that require exact formulations. At Easy Automation, we prioritize delivering cutting-edge solutions that empower your operations and drive exceptional performance. Get a custom quote today to get your facility on the right track with our specialized micro ingredient systems.